Axle counterHardwareCurrently a prototype is under test that implements a single axle sensor based on two light barriers for detection of wheel flanges and the direction of travel. The light barrier mechanical implementation is described on the pages of Michael Weinert SoftwareSoftware update over LocoNet is available with the IPL protocol using a BootLoader. The current test version supports software update, configuration over the SV protocol, 1kHz polling of the sensor inputs and display with status LEDs.

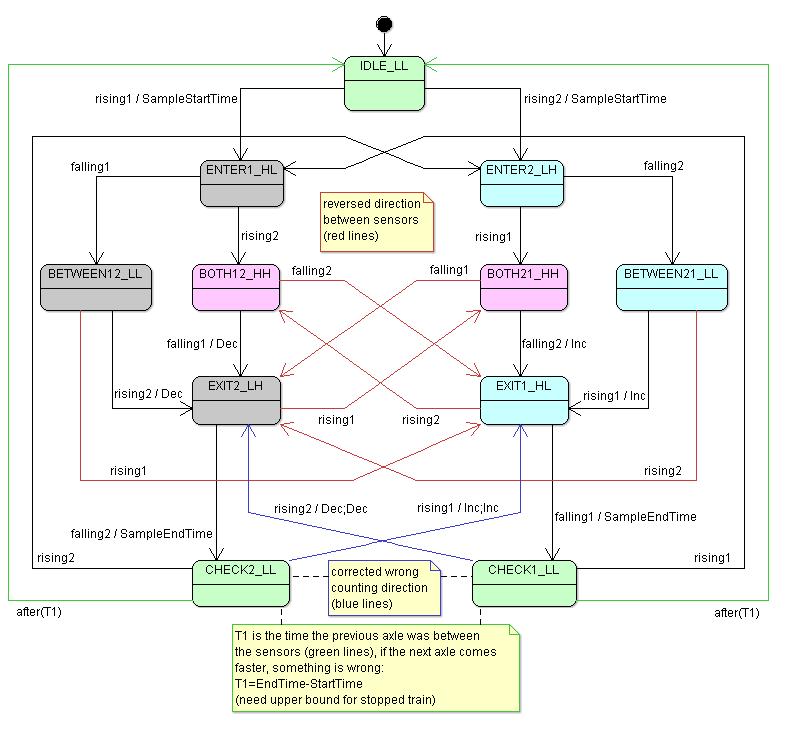

The logic for evaluation of the input signals for generation of counter information is currently under review. The following state maschine is a request for comments: State Chart

States

The state names are choosen by the following rule: They begin

with a human readable part and are followed by the state of the

sensor inputs that lead to this state. H=blocked, L=free, left

one is sensor 1, right one is sensor 2. Example: TransitionsThe transitions are composed of a name for the edge type (rising = getting blocked = L ⇒ H, falling = becoming free = H ⇒ L), followed by the number of the sensor that it applies to. Paths through the chart

The nominal path for a flange that enters over sensor 1 as shown in

the diagram above is green-grey-green and leads to a counter decrement

(shown by action Timing

In case of a direction change on a barrier or due to a

detection error, the state maschine cound get confused

and interpret wrongly, whether an axle is between the

barriers or not. This error situation can only be caught

by timing analysis. The idea is that the time the axle

stays between the barriers is much shorter than the time

between two axles passing the sensor.

Therefore the time is measured for

a flange staying on the sensor area between the two rising

edges - see actions

When the flange is assumed to leave the sensor and the end time

gets sampled, the state maschine does not directly go to

LocoNet message to report counter stateWe need a LN message that can carry an address for the sensor and a counter value. The current plan is to abuse the message OPC_ANALOGIO for this purpose. Message format

Usage of data fields

|

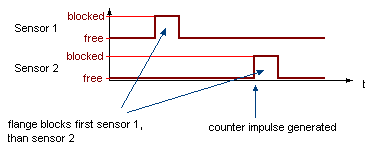

The main design

driver is the fact that the light barriers have a distance of 3,5mm,

which is space enough for a wheel flange to be in between without

being recognized by the sensor. The detection zones do not overlap.

Therefore tricky logic is needed to be sure to count in the right direction.

The following graphic shows the nominal sequence of events:

The main design

driver is the fact that the light barriers have a distance of 3,5mm,

which is space enough for a wheel flange to be in between without

being recognized by the sensor. The detection zones do not overlap.

Therefore tricky logic is needed to be sure to count in the right direction.

The following graphic shows the nominal sequence of events: